Magnetic Belt Conveyor: A Revolutionary Resolution for Environment friendly Materials Dealing with

Magnetic Belt Conveyor: A Revolutionary Resolution for Environment friendly Materials Dealing with

Blog Article

Magnetic Belt Conveyor are a important service for material handling, particularly in sectors where the transport of iron materials is necessary. These bearers combine magnetic powers along with standard belt systems, providing an effective method for relocating metal products without the demand for extra hands-on assistance. The electromagnetic field that these conveyors produce is perfect for moving ferrous components including steel, iron, and also aluminum, which would or else be actually difficult to manage making use of conventional conveyor bodies. The integrity and also accuracy with which Magnetic Belt Conveyor transportation components produce all of them crucial in fields like recycling, production, exploration, and also food items processing. Their potential to handle complicated components securely and also effectively helps in streamlined functions, lessening labor costs as well as boosting overall performance.

The major advantage of a magnetic belt conveyor exists in its capacity to move iron products tightly and also effectively. Iron components like steel, iron, and aluminum are typically utilized all over several business, but these products typically found difficulties when it comes to taking care of and also transportation. With magnetic belt bearers, the magnetics integrated right into the body provide a company hold on these products, stopping all of them coming from slipping or dropping during transport. This is actually especially helpful in reusing facilities, where fragment metals need to become sorted and also relocated to different handling places. Through providing a approach to manage and also get the flow of metallic materials, magnetic conveyors substantially lessen the capacity for material loss, strengthen safety, and streamline the workflow in business that demand steady activity of metallics.

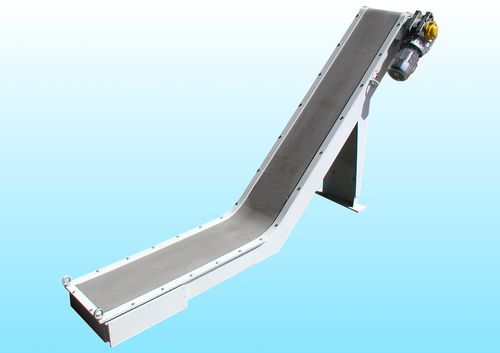

Magnetic Belt Conveyor can be found in several setups, offering adaptability and also flexibility to various industrial requirements. These bearers could be designed with level, inclined, or also bent belts, allowing them to transport materials in distinct directions as well as angles. This concept versatility enables businesses to combine magnetic conveyors in to limited areas or even complicated operations. In some scenarios, magnetic conveyors are additionally personalized to handle components of distinct dimensions and body weights, with flexible magnetic pressure to satisfy lighter or even bigger lots. For example, electromagnets could be used in specific systems to enable operators to handle the magnetic force based on the product being transferred, giving additional customization to meet certain manufacturing requirements. This versatility produces Magnetic Belt Conveyor a flexible option in business with diverse component dealing with requirements.

One of the crucial perks of Magnetic Belt Conveyor is their contribution to functional productivity. These bearers make sure the continual circulation of materials, which is actually necessary for fields that require high throughput. The magnets deal with the need for extra cautions or even hands-on intervention to hold materials in area, lowering the danger of binds, disturbances, or even hold-ups in the development method. As the bearer waistbands work easily and together, organizations experience less upkeep concerns as well as down time. In fast development atmospheres, including food items handling collections or even vehicle manufacturing plants, the consistent movement of components promoted through magnetic belt conveyors is actually critical in preserving efficiency. Their capability to function properly, even under asking for disorders, produces all of them an fundamental part of many assembly line and industrial configurations. To acquire more information please check out Tecnimetal

Another benefit of Magnetic Belt Conveyor is their toughness and low servicing needs. Conventional conveyors can experience substantial deterioration as a result of to rubbing between the waistband as well as the components being carried. This friction commonly leads to waistband destruction, mechanical failures, and the need for recurring servicing. Magnetic Belt Conveyor, having said that, knowledge much less friction due to the fact that the magnetic force has the products in location without the necessity for physical contact. Because of this, the belts usually tend to last longer and experience far fewer problems, minimizing the demand for continuous repair work and also substitutes. In fields that take care of heavy or even unpleasant products, Magnetic Belt Conveyor deliver a even more dependable and also cost-efficient solution for material transport. Furthermore, their low servicing nature creates them easier for services, as they require far fewer sources to maintain the system managing properly.

The safety advantages of Magnetic Belt Conveyor also support their wide-spread make use of. Handling massive or even pointy steel things by hand can pose significant risks to workers in numerous markets, including possible decreases, pressures, or various other injuries. Through automating the transit of ferrous materials, magnetic bearers remove the demand for straight interaction with harmful materials, reducing the threat of collisions. This automated component handling system likewise minimizes the chances of things being actually misaligned or even dropping off the conveyor, which can cause crashes or product harm. In markets like recycling, where huge volumes of junk metallic require to be actually managed, Magnetic Belt Conveyor not only strengthen safety but additionally improve overall operational effectiveness by reducing the amount of time spent by hand sorting or even managing materials. The combination of magnetic conveyors into automated bodies even more improves office safety.